Why Chain of Custody Isn’t Optional — It’s Essential for Responsible Hemp

In the race toward decarbonization and sustainability, one of the biggest blind spots is material-level transparency. Carbon Report’s work on enabling chain of custody for parts and materials highlights a fundamental truth: you cannot credibly claim carbon or sustainability benefits unless you track your materials from source to product.

Medical Applications of Bast Fiber: Hemp and Flax in Next-Generation Healthcare

Bast fibers such as hemp and flax are not only shaping the future of textiles and regenerative agriculture—they are also emerging as promising materials in medical science. Recent peer-reviewed studies highlight how these natural fibers can deliver unique advantages in wound care, surgical implants, orthopedic devices, and infection control.

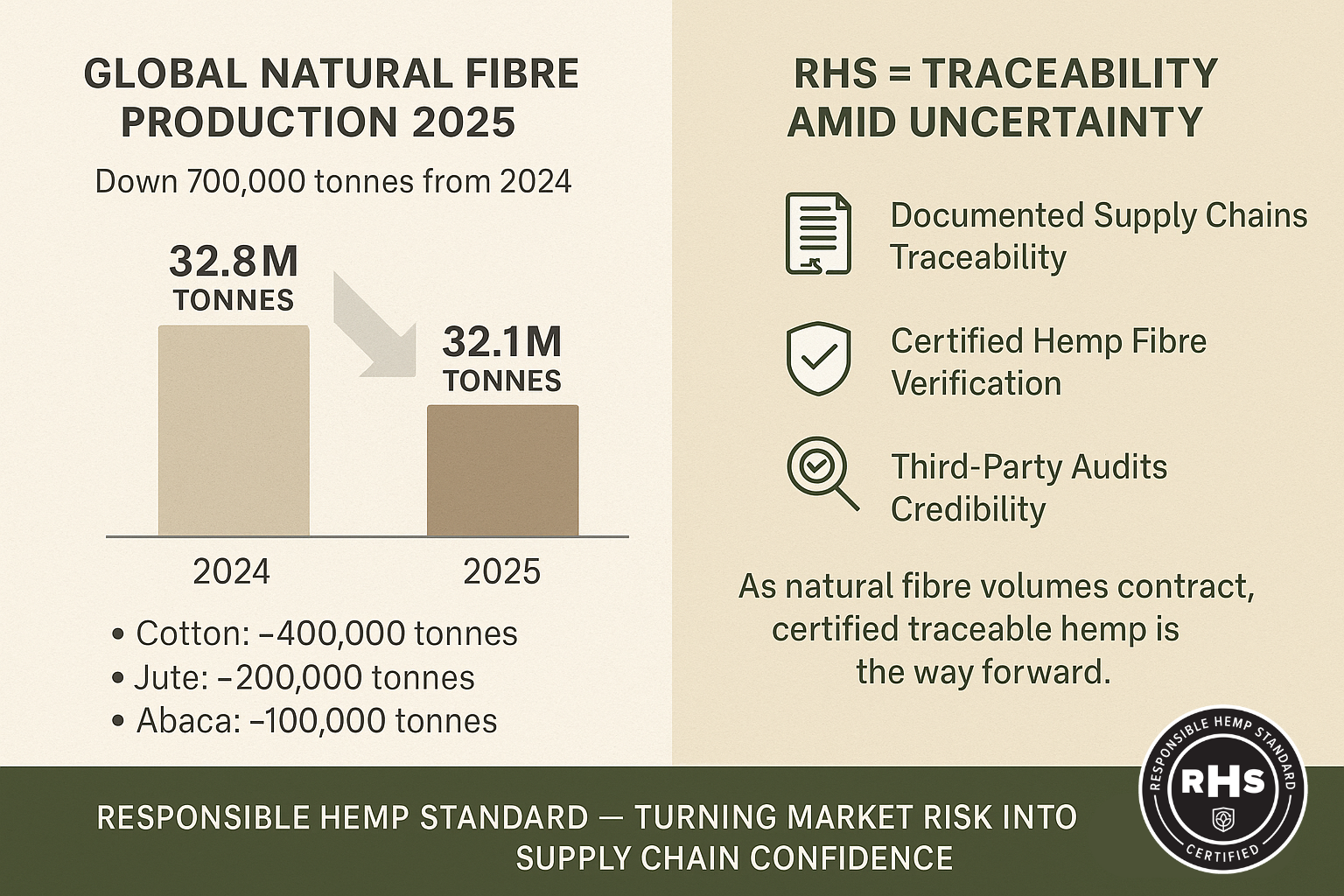

Natural Fiber Production Slips in 2025: Why Traceability and Certification Are More Critical Than Ever

The Discover Natural Fibres Initiative (DNFI) has released its August 2025 World Natural Fibre Update, revealing a significant downward revision in projected global natural fibre production. Production is now expected to reach 32.1 million tonnes in 2025—a decrease of 700,000 tonnes from 2024 and 600,000 tonnes lower than prior estimates in July.

Turning Supply Chains into Trust Chains

A factory in a developing country must “dress for success” if it wants to capture the attention of global brands. This goes far beyond producing textiles—it is about building trust and projecting reliability, transparency, and innovation.

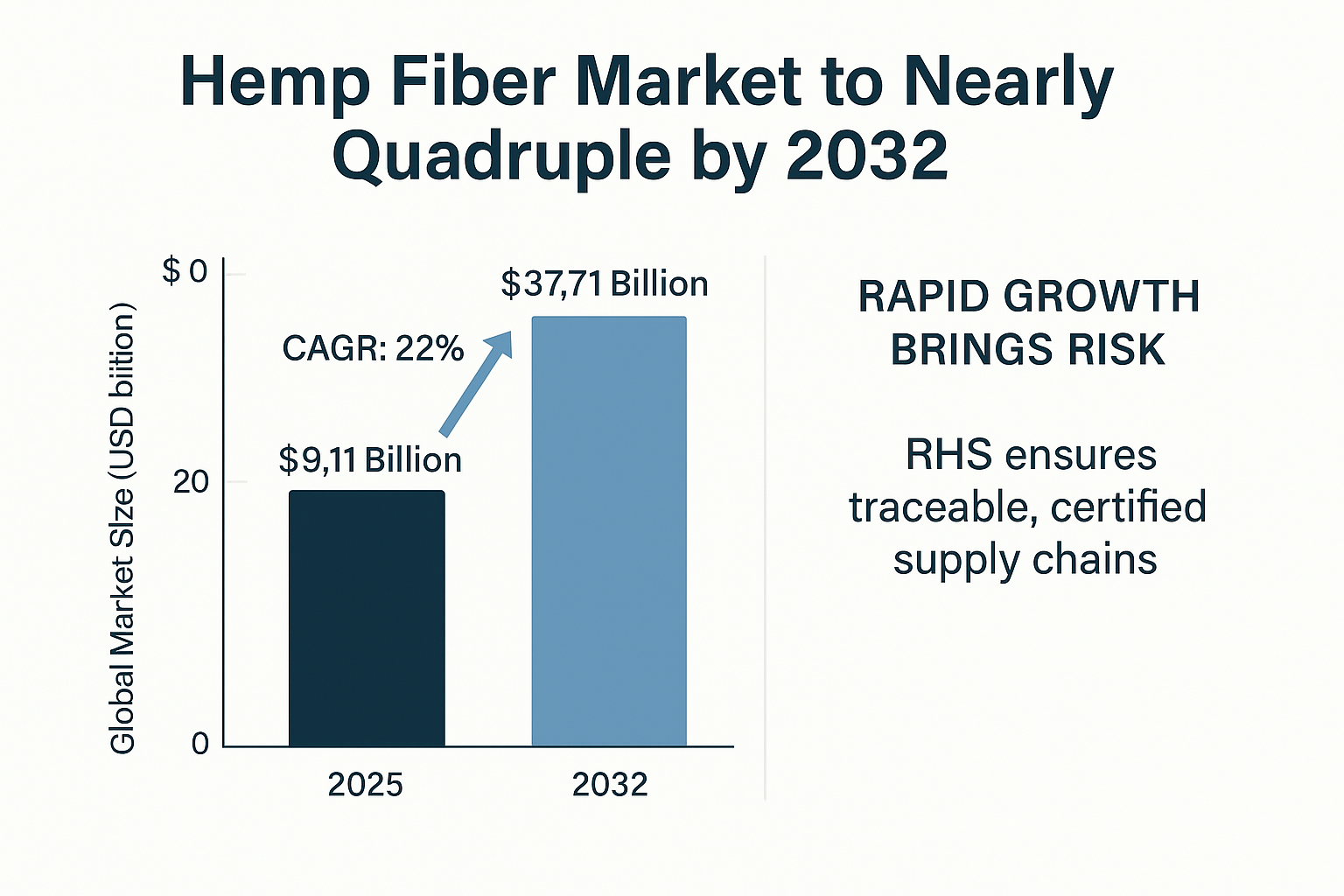

Hemp Fiber Market to Nearly Quadruple by 2032 — Why Traceability Matters Now

The global hemp fiber market is on the brink of explosive growth. According to a recent industry forecast, the market is projected to expand from $9.11 billion in 2025 to $37.71 billion by 2032, growing at a compound annual growth rate (CAGR) of 22–22.5%.

This surge reflects hemp’s rising role across multiple industries — from textiles and fashion to automotive composites, green construction, and biobased materials.

The Invisible Commodity: Why Global Trade Fails to Measure Hemp — and How Certification Can Fix It

Industrial hemp is one of the most promising sustainable materials for textiles, food, and wellness. Yet according to a new United Nations Conference on Trade and Development (UNCTAD) report, hemp remains largely invisible in global trade statistics.

The report, Measuring Global Exports of Industrial Hemp Products, reveals just how difficult it is to track hemp’s true economic footprint. For brands and textile manufacturers, this lack of visibility poses risks — from missed opportunities to supply chain greenwashing claims.

That’s where the Responsible Hemp Standard (RHS) comes in.

Sustainable Sun Protection: The UV-Blocking Benefits of Bast Fibers

Bast fibers—such as hemp, flax, jute, and ramie—have a natural edge when it comes to sun protection. Their chemical composition includes lignin and phenolic acids, such as ferulic acid, which are known for their ability to absorb UV rays

The Cost of Doing Nothing: The Risk of Sourcing and Making Claims on Non-Certified Hemp

In today’s global apparel market, transparency isn’t just a value. It’s a requirement. For brands eager to tap into the appeal of natural fibers like hemp, the temptation to make sustainability claims without certification may seem harmless. But in a fast-evolving regulatory and consumer landscape, sourcing non-certified hemp is no longer a neutral choice. It’s a liability.

What RHS Guarantees: Turning Sustainability Claims into Actionable Standards

In today’s fashion industry, saying you “support sustainability” is no longer enough. As EU due diligence rules tighten and greenwashing is increasingly scrutinized, brands need proof, not promises. That’s where the Responsible Hemp Standard (RHS) comes in. Whether you're a sourcing lead, a sustainability manager, or a designer exploring innovative natural fibers, RHS offers a reliable framework to turn your ambitions into action.

Beyond Polyester and Cotton: Why It’s Time for Traceable Bast Fibers

Last month, our team walked the show floors of Functional Fabric Fair and Texworld NYC — two of the most influential sourcing events in the textile industry. While we were energized by the scale of innovation on display, one thing stood out immediately:

Natural fibers — especially bast fibers — were vastly underrepresented.

How EU Sustainability Policies Are Going to Shape the Hemp Fiber and Apparel Supply Chain

The European Union is fundamentally reshaping global textile supply chains through an ambitious suite of sustainability policies that will transform how hemp fiber moves from field to finished product. Unlike cotton and other conventional fibers struggling to retrofit transparency into established systems, hemp presents a unique opportunity: the chance to "get traceability right from day one" in a regulatory environment that rewards verified sustainability claims with market access and consumer trust.

From Claim to Confidence: Why Third-Party Certification Builds Consumer Trust

In today’s fashion marketplace, trust is the new currency. Consumers are more aware, more curious, and more critical than ever before, especially when it comes to sustainability. They want to know: Was this product really made responsibly? Are these materials actually low-impact? What does “sustainable” even mean anymore?

Building Reliable Supply Chains for Hemp Fiber in the Textile Industry

Building a reliable supply chain for hemp fiber in the textile industry definitely comes with its challenges. There’s a lot of work to be done due to limited infrastructure, fluctuating availability of raw materials, and the fact that information can be inconsistent.

The Fiber Future Is Bast: Why Hemp, Flax, and Jute Are Regenerative Materials to Watch

In the global push for more sustainable fashion, one category of natural fibers is beginning to stand out for its environmental performance, regional relevance, and scalability: bast fibers. Derived from the inner bark of plants like hemp, flax, and jute, bast fibers are renewable, low-impact, and uniquely suited to support the textile industry’s regenerative future.

How RHS Supports Farmers and Processors in Building a Scalable Hemp Fiber Supply Chain

As the demand for natural, regenerative materials rises, industrial hemp is gaining attention across the textile sector, for good reason. It’s fast-growing, low-input, and offers real potential to lower the carbon footprint of apparel, fashion, and home textiles. However, scaling hemp fiber isn’t just about environmental potential. It’s about infrastructure, risk, and trust—starting at the very first step of the supply chain.

Born, Raised, and Made In: Why Traceable Stories Matter

In today’s saturated fashion market, customer loyalty isn’t just about price, fit, or fast-changing trends — it’s about trust.

What truly resonates with modern consumers is the story behind the product. Who made it? Where did the materials come from? Was it sourced responsibly?

Why Source from RHS-Certified Suppliers?

For brands seeking scalable, verified, low-impact natural materials, Responsible Hemp—industrial hemp certified under the Responsible Hemp Standard (RHS)—offers a credible path forward. Whether you're aiming to reduce your material footprint, comply with ESG reporting, or meet consumer expectations for traceability and transparency, sourcing from RHS-certified suppliers gives you the assurance, data, and storytelling power to move with confidence.

How RHS Can Help Break the Industrial Hemp Chicken-and-Egg Cycle

The apparel market, like many other industries, is eager for environmentally low-impact, natural materials. Hemp consistently tops the list, for good reason. It requires fewer inputs than cotton, builds soil health, and offers strength as a durable bast fiber. However, despite this promise, brands still struggle to source hemp at scale.

Translating Sustainability: How to Connect with Consumers about the Benefits of Responsible Hemp and Natural Fibers

For all the progress being made in building sustainable supply chains, one challenge remains persistent: how do we effectively communicate the value of Responsible Hemp and other traceable and certified natural fibers to the consumer?

Why Take the Step to Get RHS Certified?

Getting certified as a textile mill isn’t just a box to tick—it can change the game. From operations and sales to your reputation and your impact on the planet, the Responsible Hemp Standard (RHS) certification opens doors. Here’s a quick look at the advantages of getting RHS certified and the considerations.